Schobertechnologies is your competent partner for rotary offline & inline converting solutions for the finishing of circuit boards, bipolar

plates and membranes for fuel cells. These rotary finishing technologies include calendering, embossing, cutting and punching.

Converting solutions:

- Combi-tools mounted on carrier shaft

- Combination of embossing and die cutting in the same tool (split design)

Embossing solutions:

- Special pattern design for the finishing of bipolar plates

Rotary die cutting solutions:

- Proven finishing and product handling design for sensitive „membranes“

Rotary punching solutions:

- Punching tools for dense patterns with exchangeable punches and dies

Cut & Place:

- Simple cross cut or complex shape cut of web-fed products

- Proven handling technology to place the die cut part onto a continuously moving web (in fixed or variable distance)

Rotary Converter (RVA)

- Calendering and embossing modules

- Die cutting and punching modules

- Product delivery

R&D center:

- Rotary test tools available for various embossing „punching and die cutting patterns

Rotary web finishing offers multiple advantages.

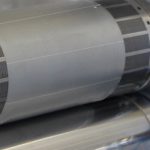

CCM (Catalyst Coated Membrane), component of MEAs (Membrane Electrode Assemblies), is quite a difficult and sensitive material to process, mainly when it comes to room temperature and humidity variations. However, rotary die cutting technology has proven its efficiency during the converting and processing, when integrated in fuel cell assembly lines.

Other materials used are GDM (Gas Diffusion Layer) and PEM (Polymer Electrolyte Membrane).