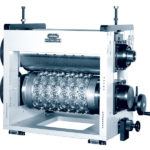

The punching technology has been developed and refined through Schober´s long standing experience in the printing, packaging, hygiene and medical field spanning over several decades. Based on the material, punching applications with web width of up to 2000 mm and speeds of up to 600 m/min can be performed clean and burr-free. Waste removal is achieved without any problems even for tight punching patterns with hole sizes as small as 0,5 mm.

Benefit from our wide selection of high precision tools and built-in modules for the production of:

– Smooth and serrated punching for business forms, datamailers, tea bags and -labels, self-adhesive labels and price tags, …

– Contour and profile punching for corner cuts of ATB- and ATB2- tickets, boarding passes, wallets, parking tickets, banknotes, batteries / energizers, security labels, smart cards, solar panels, datacards, diagrams, test strips, file holes, meat tray inserts, film holes, security documents, …

– surface holes for fruit and vegetable wrapping foils, band aids, …

Schober offers the largest spare parts inventory in Europe for:

– Round, square and profile punches and die.

– Crimp punches and die.

– Circular knives.

– Perforating and cutting wheels and blades.

– Quick change clamping bars.

Early Schober engineers’ recognized the need to combine different types of material to increase the life of our tools.

Count on our consultants and send us your product sample or drawing.