for high-end

products

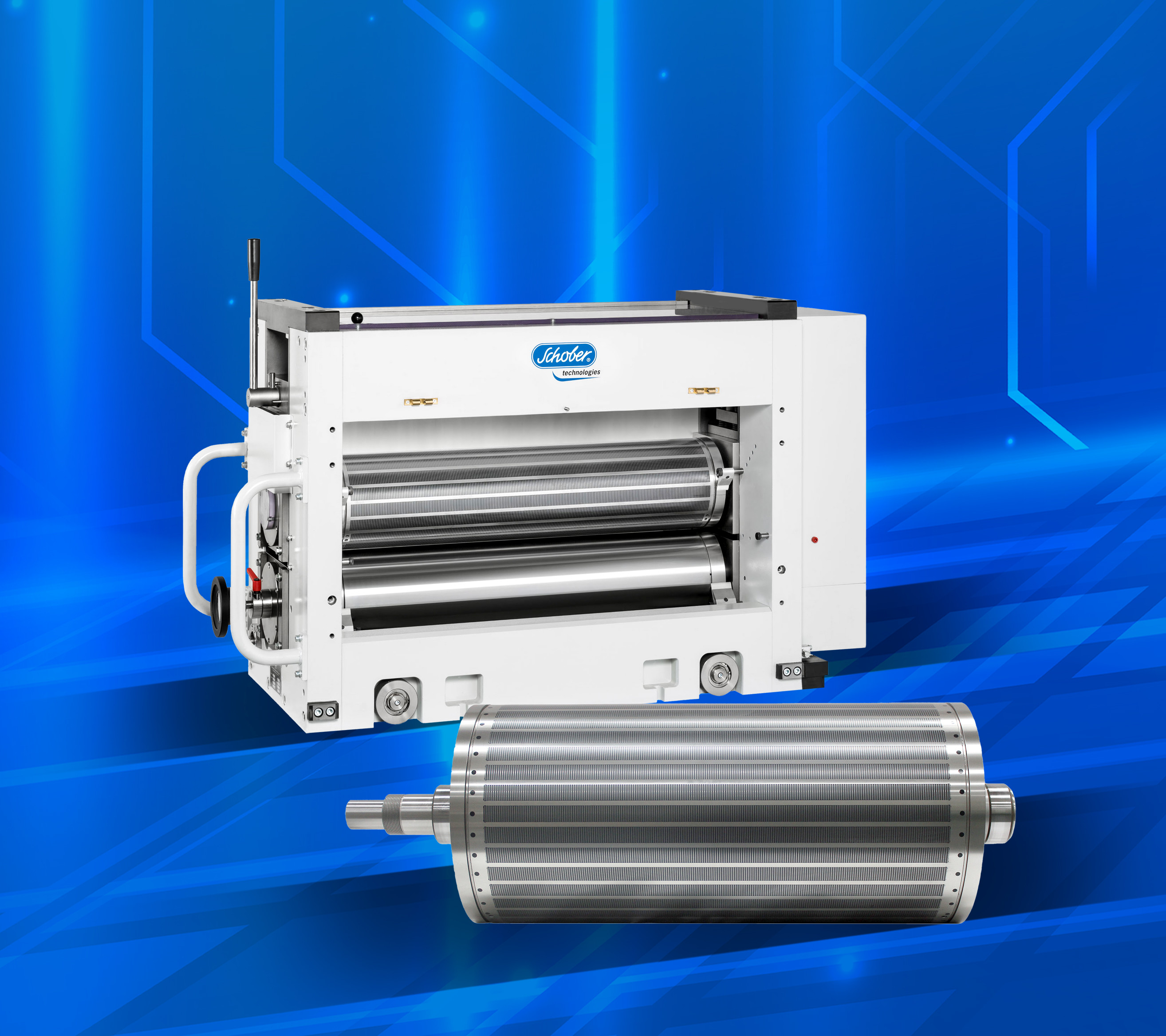

Schobertechnologies is one of the leading specialists in the development and manufacturing of rotary tools and specialty machines widely used in film, foil, cardboard, nonwovens and paper converting industries.

The production systems of the Schobertechnologies RSM IML series are among the most innovative and efficient machines for manufactruing inmold labels.

The new high-tech Schobertechnologies machines of the RSM HD series have been specially developed for processing digitally printed films and packaging materials.

The rotary punching technology is used when the particles to be removed are too small for a cutting process or cause difficulties during removal.

We provide you with all the parts you need for highly efficient cutting, perforating, punching, creasing and embossing. We offer you punches, die bushes, cutting & perforating lines and circular knives - you can also have your tools professionally and sustainably sharpened by us.

Schobertechnologies specializes in the manufacturing of large, high-precision XXL magnetic cylinders. Our high-quality XXL magnetic cylinders have been developed with a high level of technical expertise and guarantee maximum precision and holding force during the grooving and cutting process.

The TECHNOVATION WORLD is a web application in which innovative finishing technologies can be experienced interactively and in 3D. Detached from time and space, you can enter the world anytime and anywhere and start a new digital adventure.

Experience Schobertechnologies’ technology highlights live. Schobertechnologies presents innovative products, solutions and technologies at all industry-relevant exhibitions worldwide. We look forward to meeting you in person at a show and presenting our innovations.